Grinding Safety: Best Practices for Precision and Protection

Grinding — also known as surface grinding — is a precision machining operation used to remove material using abrasive tools like wheels, belts, or compounds. Whether you’re smoothing surfaces or achieving tight tolerances, grinding remains one of the most accurate material removal methods in modern industry.

But with precision comes risk. In this blog, we’ll explore the fundamentals of grinding, its potential hazards, and essential safety practices every worker should follow.

🔧 What Is Grinding?

At its core, grinding is a cutting process. It uses abrasive grains bonded together in a wheel or disk, which act as microscopic cutting tools. As the abrasive wheel rotates against the workpiece, it shears off small particles of material — achieving a smooth finish.

Due to the friction involved, grinding can generate substantial heat, which is why coolants are often used to prevent overheating and preserve material integrity.

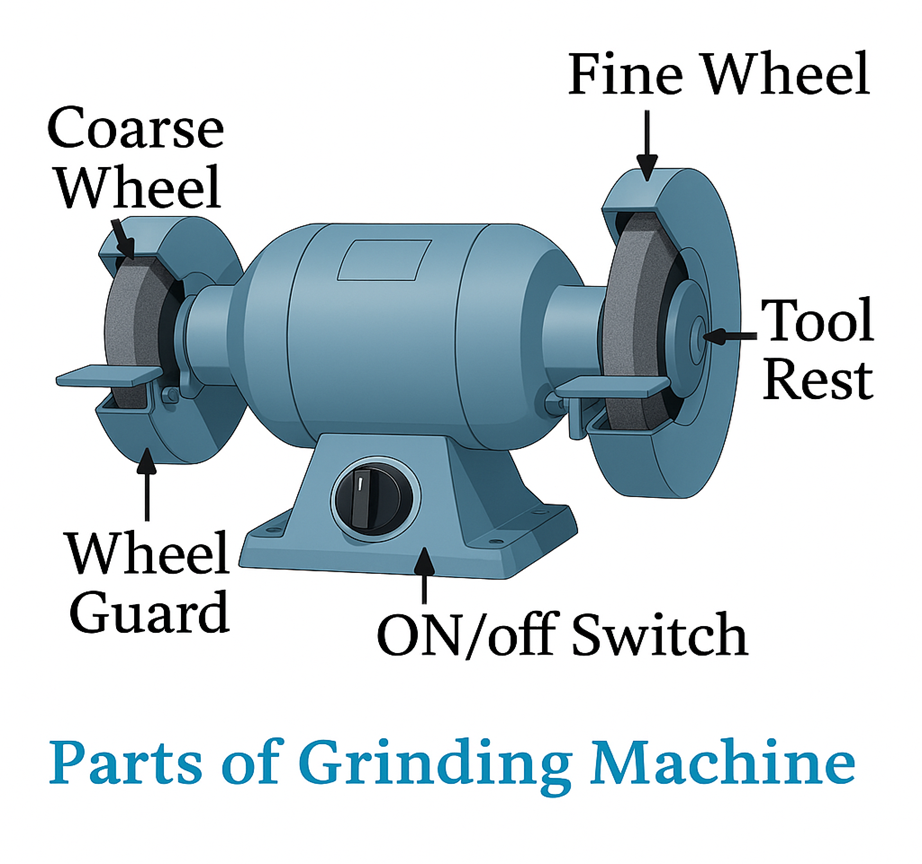

🛠️ Types of Grinders You’ll Encounter

Depending on the job and environment, you may work with:

- Portable hand-held grinders (air- or electric-powered)

- Pedestal grinders

- Precision grinders, such as surface or cylindrical grinders

Each type has specific safety requirements and is suited to different tasks.

⚠️ Common Hazards in Grinding Operations

Grinding may seem straightforward, but it comes with a set of serious risks:

- Cuts and abrasions from contact with rotating wheels

- Noise-induced hearing loss from prolonged exposure

- Wheel shattering, leading to flying debris and potential injuries

- Eye injuries from high-speed particles

- Muscle strain from poor posture or manual handling

Understanding these risks is the first step to working safely.

🧠 Before You Start: Planning and Preparation

Good planning leads to safe execution. Before beginning any grinding task:

✅ Select the correct wheel for the material and task

✅ Inspect the grinder — ensure guards are in place, leads are undamaged, and the tool is properly tagged

✅ Set up the workspace — ensure good lighting and an ergonomic position to avoid strain

✅ Keep the area clean — remove any debris or dust from previous work

🧤 Grinding Safely: Practical Guidelines

Your behavior at the workstation is just as important as the tools you use. Follow these best practices:

👓 Personal Protective Equipment (PPE)

- Wear safety glasses and a full-face shield — always

- Use ear protection (earmuffs or plugs)

- Wear gloves only if appropriate for the task (never loose-fitting)

🔍 Equipment Checks

- Inspect the grinding wheel for cracks or damage

- Ensure the wheel is properly mounted with correct flanges and collars

- Never apply side pressure to cutting wheels

🏗️ During Operation

- Start grinding gently; don’t overload the wheel

- Use dust extraction systems or ventilation

- Secure your workpiece firmly — avoid “live” grinding where it can move

- Stay focused — never leave the grinder running unattended

🧹 After the Job

- Clean up all dust and debris to reduce slip and eye injury risks

- Store tools and PPE properly for the next use

📣 Reporting Hazards and Faults

If you see something wrong, act immediately:

- Fix minor hazards (like spills) yourself if it’s safe.

- If not fixable, isolate the hazard and inform others.

- Report the issue to your supervisor so corrective action can be taken.

Ignoring a small fault today could cause a serious incident tomorrow.

✅ Nutshell

Grinding is essential to modern fabrication and engineering, but it must be done with care. By planning ahead, using proper PPE, and following safe work practices, you can keep yourself and your team safe — while still delivering precision work.

Stay safe. Stay sharp. And never let your guard down around the grinder.