Developing a Safe and Effective Lifting Plan for Crane Operations

Date 1st September`2025 – Saeed Pasha

Lifting operations are an essential part of construction, industrial, and infrastructure projects. However, they also pose significant risks if not planned and executed properly. A lifting plan serves as a detailed, pre-determined document that acts as the blueprint for safe and efficient lifting operations. It not only defines how the lift will be conducted but also ensures compliance with legal requirements and industry’s best practices.

What is a Lifting Plan?

A lifting plan is a formal document that outlines all the critical aspects of a lifting operation before it begins. It is prepared and reviewed by competent, qualified personnel to ensure safety, efficiency, and compliance. The plan serves as a communication tool for all stakeholders involved, minimizing misunderstandings and risks.

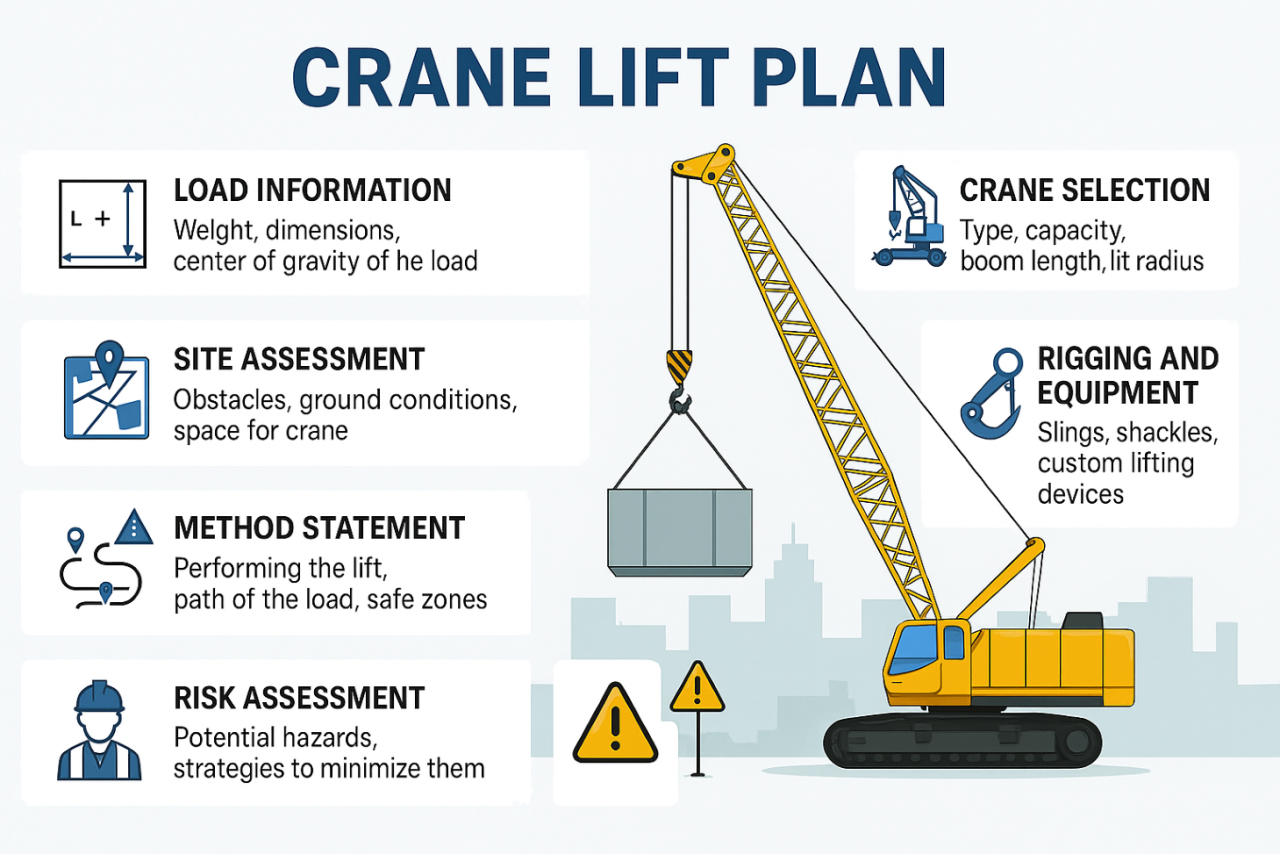

Key Components of a Lifting Plan

Load Information

Details about the load, including weight, dimensions, and center of gravity, are crucial to selecting the right equipment and rigging method.

Crane Selection

Identification of the crane type, its lifting capacity, boom length, and lift radius ensures that the chosen crane is suitable for the operation.

Site Assessment

Evaluation of site conditions, such as ground stability, obstacles, and maneuvering space, reduces the risk of accidents.

Rigging and Equipment

Specifications of slings, shackles, spreader bars, and any custom lifting devices must be included and verified.

Method Statement

A step-by-step description of the lifting process, including load path, exclusion zones, and emergency procedures.

Risk Assessment

Identification of potential hazards (e.g., proximity to power lines, ground instability, load swinging) with mitigation measures.

Personnel and Responsibilities

Clear assignment of roles for crane operators, riggers, signalers, and supervisors, ensuring all are competent and trained.

Weather and Environmental Factors

Consideration of wind speed, rain, visibility, and other environmental conditions that may impact lifting safety.

Purpose of a Lifting Plan

- Enhancing Safety: Ensures hazards are identified and mitigated before operations begin.

- Ensuring Compliance: Meets legal requirements such as OSHA standards, ILO conventions, and national safety regulations.

- Improving Efficiency: Reduces delays, damage, and downtime by providing a clear, structured plan.

- Facilitating Communication: Aligns all stakeholders for a safe and successful lifting operation.

Planning and Competence

The complexity of a lifting plan depends on the nature of the operation.

- Routine lifts (e.g., small mobile crane operations) may be planned by the operator or slinger.

- Complex lifts (e.g., tandem lifts using multiple cranes) require a written plan developed by a competent person with specific training and expertise.

The planner must have sufficient theoretical and practical knowledge of lifting equipment, legal requirements, and risk management.

Critical Risk Factors in Lifting Operations

A lifting plan must address foreseeable risks, including:

- Working under suspended loads

- Poor visibility during lifts

- Attaching, detaching, and securing loads

- Proximity hazards (power lines, buildings, excavations)

- Risk of overturning or overloading

- Equipment integrity and pre-use checks

- Environmental challenges (wind, uneven terrain)

- Lifting of personnel (requires higher safety factors)

- Equipment Strength, Stability, and Positioning

Equipment Strength, Stability, and Positioning

- Strength and Stability: Equipment must have adequate strength with a safety margin to withstand combined forces.

- Positioning: Mobile cranes should be placed on stable ground, away from excavations or underground utilities. Loads must not be lifted over people unless unavoidable, in which case exclusion zones must be established.

- Preventing Falling Loads: Use of hydraulic check valves, multiple ropes, and safety nets where applicable.

Working Under Suspended Loads

As a rule, no one should work under suspended loads. If unavoidable:

- Establish danger zones beneath suspended loads.

- Restrict access with barriers and signage.

- Implement strict communication protocols.

- Supervision of Lifting Operations

Supervision levels should be proportionate to risk.

- Routine lifts: May not require constant supervision if conducted by competent operators.

- Complex or unusual lifts: Require continuous oversight and coordination by a lift supervisor.

Employers must periodically reassess worker competence to ensure ongoing safety.

Conclusion

A lifting plan is far more than a formality—it is a vital tool to safeguard lives, protect property, and ensure operational efficiency. The degree of planning must be proportionate to the complexity and risk of the lift. With the right combination of competent personnel, risk assessment, equipment suitability, and clear communication, lifting operations can be carried out safely and successfully.

References

- Occupational Safety and Health Administration (OSHA), 29 CFR 1926.1412 – Cranes and Derricks in Construction.

- Health and Safety Executive (HSE UK), Lifting Operations and Lifting Equipment Regulations 1998 (LOLER).

- International Labour Organization (ILO), Convention C155 – Occupational Safety and Health Convention, 1981.

- International Labour Organization (ILO), Convention C187 – Promotional Framework for Occupational Safety and Health, 2006.

- ISO 12480-1:2003, Cranes – Safe Use – General