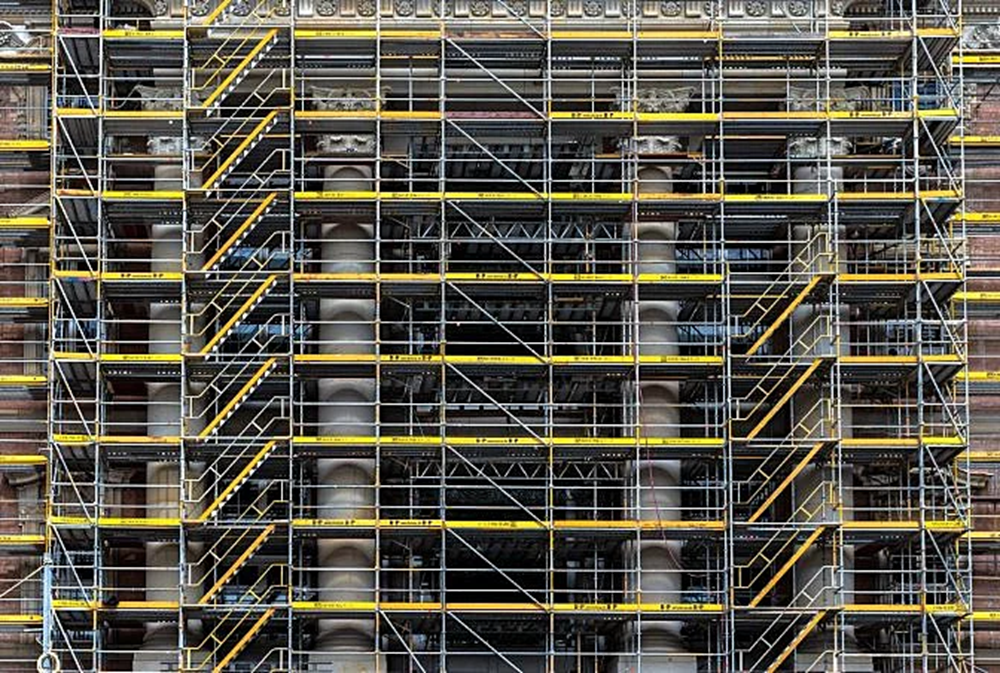

What is Scaffolding?

Scaffolding, also referred to as a scaffold or staging, is a temporary structure used to support individuals working at height. Typically constructed from metal pipes and wooden planks, scaffolding provides a stable platform for construction workers, inspectors, cleaners, and others accessing hard-to-reach areas.

The origins of scaffolding date back over 17,000 years, with archaeological evidence indicating its use in the Paleolithic era for creating cave paintings in Lascaux. Throughout history, ancient civilizations such as those in Egypt and China employed basic wooden scaffolds tied with rope to assist in construction tasks.

In modern times, scaffolding systems have evolved into more sophisticated designs, using advanced materials and configurations. This overview explores its current applications, types and components, methods of assembly, the debate around renting versus purchasing, and how technology—particularly drones—is revolutionizing access to elevated work areas.

Definition and Purpose

Scaffolding is a provisional framework erected to allow safe access and working conditions at elevated or otherwise inaccessible locations. It is essential in construction, maintenance, and inspection work involving buildings, bridges, and other structures, offering support for both workers and materials.

Advantages of Scaffolding

Scaffolding continues to be a highly effective solution for work at height due to the following benefits:

- Improved Access: Scaffolding enables safe and easy access to otherwise difficult-to-reach areas of a structure.

- Stability and Balance: Provides a firm platform, allowing workers to perform tasks with confidence and precision.

- Quick Assembly: Modern scaffolds are relatively fast to erect and dismantle.

- Durability: Whether made from steel or treated wood, scaffolds can withstand long-term use under proper maintenance.

- Enhanced Safety: A well-designed scaffold system significantly minimizes the risk of falls and other accidents at height.

- Efficient Movement: Bridging sections can reduce walking distance across a site, saving time and reducing fatigue.

Risks and Hazards Associated with Scaffolding

Despite its benefits, scaffolding presents serious risks, especially when improperly erected or maintained.

Key Statistics (OSHA, U.S.):

- Approx. 4,500 injuries and 60 fatalities occur annually due to scaffold-related incidents.

- Falls from scaffolds represent about 25% of all construction-related deaths.

- Around 72% of injured workers cite plank failure, slips, or falling objects as causes.

- Inadequate fall protection is the most frequently cited OSHA violation on construction sites.

Common Hazards:

- Structural Defects: Weak or damaged components can lead to collapse.

- Falling Debris: Tools or materials falling from platforms pose serious risks.

- Weather Conditions: Rain, snow, and temperature changes can compromise safety.

- Overloading or Unsafe Placement: Exceeding capacity or proximity to hazards increases accident likelihood.

- Lack of Training: Workers need specialized training for scaffold use and assembly.

- Substandard Materials: Inadequate planking or faulty support systems increase fall risk.

- Negligence or Inexperience: Unskilled workers or careless behavior can lead to accidents.

- Insufficient Safety Gear: Harnesses, helmets, and other PPE must be readily available.

- Improper Construction: Missing bracing, guardrails, or misaligned connections contribute to failure.

- Poor Maintenance: Worn-out parts, rust, or slippery surfaces reduce the structure’s integrity over time.

Primary Uses of Scaffolding

Scaffolding is used across various industries for both common and specialized tasks:

- Cleaning: Especially for high-rise buildings, scaffolds support safe window cleaning.

- Construction: From residential buildings to skyscrapers, scaffolds enable workers to perform tasks at height efficiently.

- Industrial Inspection: Scaffolds allow inspectors to access internal and external areas of industrial assets such as boilers and tanks for visual and non-destructive testing.

- Maintenance: Following inspections, scaffolds help maintenance teams safely repair or replace faulty components.

- Special Applications: Used for constructing art installations, concert stages, grandstands, exhibition booths, ski ramps, observation towers, and structural shoring.

Modern Alternatives: Drones for Inspection Work

While scaffolding is effective, it is not without its limitations, including time-consuming setup, high costs, and inherent risk. Recent advancements in drone technology offer safer, faster, and more economical alternatives—particularly for inspection tasks.

Advantages of Using Drones:

- Safety: Drones eliminate the need for inspectors to physically climb scaffolds, significantly reducing exposure to fall risks.

- Cost Savings: Erecting scaffolding for short-term inspections can be expensive. Drones offer a reusable and lower-cost alternative.

- Downtime Reduction: Because drones don’t require time to build access systems, inspections are faster, minimizing disruption to operations.

- Speed & Flexibility: Drones can rapidly capture data from multiple angles and hard-to-reach areas, outperforming manual inspections in terms of efficiency.

Modern drones like the Flyability Elios 3 are equipped with visual cameras and can be fitted with additional sensors for ultrasonic testing or radiation detection. These features make drones suitable for industrial environments where traditional access methods would be slow or dangerous.

NutShell

Scaffolding remains an indispensable tool in the construction and inspection industries, valued for its practicality, reliability, and versatility. However, it is essential to recognize and mitigate the associated risks through proper training, adherence to safety standards, and ongoing maintenance.

As industries continue to evolve, new technologies such as drones offer promising alternatives to traditional scaffolding, particularly in inspection work. By combining time-tested practices with innovative solutions, companies can enhance both safety and efficiency on the job site.