Hazardous Area Classification

Introduction

Hazardous Area Classification (HAC) is a critical process used to identify and classify areas where flammable gases, vapors, dust, or fibers may be present in sufficient quantities to cause an explosion or fire hazard. Proper classification helps organizations design, operate, and maintain equipment and work processes safely to prevent catastrophic incidents. HAC is mandated under various international standards, such as IEC 60079, NFPA 497, API RP 505, and OSHA 1910.307, and is widely adopted by industries in Pakistan to ensure compliance and worker safety.

Where is Hazardous Area Classification Required?

HAC is required wherever there is a risk of flammable or combustible substances being released during normal or abnormal operations. Examples include:

- Chemical Storage Rooms: e.g., storage of solvents, fuels, or chemicals.

- Oil and Gas Facilities: e.g., tank farms, refineries, wellheads.

- Processing Plants: e.g., food plants with dust-producing ingredients.

- Laboratories: e.g., labs handling volatile chemicals or gases.

- Paint Shops and Spray Booths: where flammable paints or solvents are used.

These areas exist in various industrial estates in Islamabad, Lahore, Karachi and other industrial cities in Pakistan where TARMS Pakistan provides HAC consultancy and training support.

When is Hazardous Area Classification Required?

HAC is typically conducted during:

- Design Stage: For new facilities to ensure safe design of electrical and mechanical installations.

- Process Modifications: When processes change or chemicals are added.

- Periodic Reviews: To ensure existing classifications remain valid.

- After Incidents: Post-incident investigations may trigger re-classification.

Example: If a fertilizer storage shed introduces a new type of ammonium nitrate, a new HAC assessment must be done to check for potential dust explosion hazards.

Which Industries Require Hazardous Area Classification?

HAC is common in, but not limited to:

- Oil & Gas Exploration and Production

- Chemical and Petrochemical Industries

- Pharmaceutical Manufacturing

- Food Processing Mills (e.g., flour mills)

- Textile and Woodworking Industries

- Agricultural Storage (grain silos)

- Waste Treatment Plants

Each industry has unique risks based on the flammability of materials handled. For these sectors, TARMS Pakistan delivers tailored HAC studies, site-specific risk assessments and compliance audits to national and international codes.

Methodology of Hazardous Area Classification

A standard HAC process involves:

1️⃣ Identifying Sources of Release

- Equipment: pumps, flanges, tanks, reactors.

- Operations: sampling, draining, transfer points.

2️⃣ Assessing Release Frequency & Duration

- Continuous, Primary, or Secondary release.

3️⃣ Determining the Extent of Hazardous Zones

- Using recognized codes (e.g., IEC, API).

4️⃣ Defining Zone Classification

- Based on type of substance (gas/vapor or dust).

5️⃣ Documenting & Mapping

- Producing HAC drawings and reports for installation design.

TARMS Pakistan’s expert consultants provide HAC reports, mapping and training to keep your facility safe and compliant with national and international best practices.

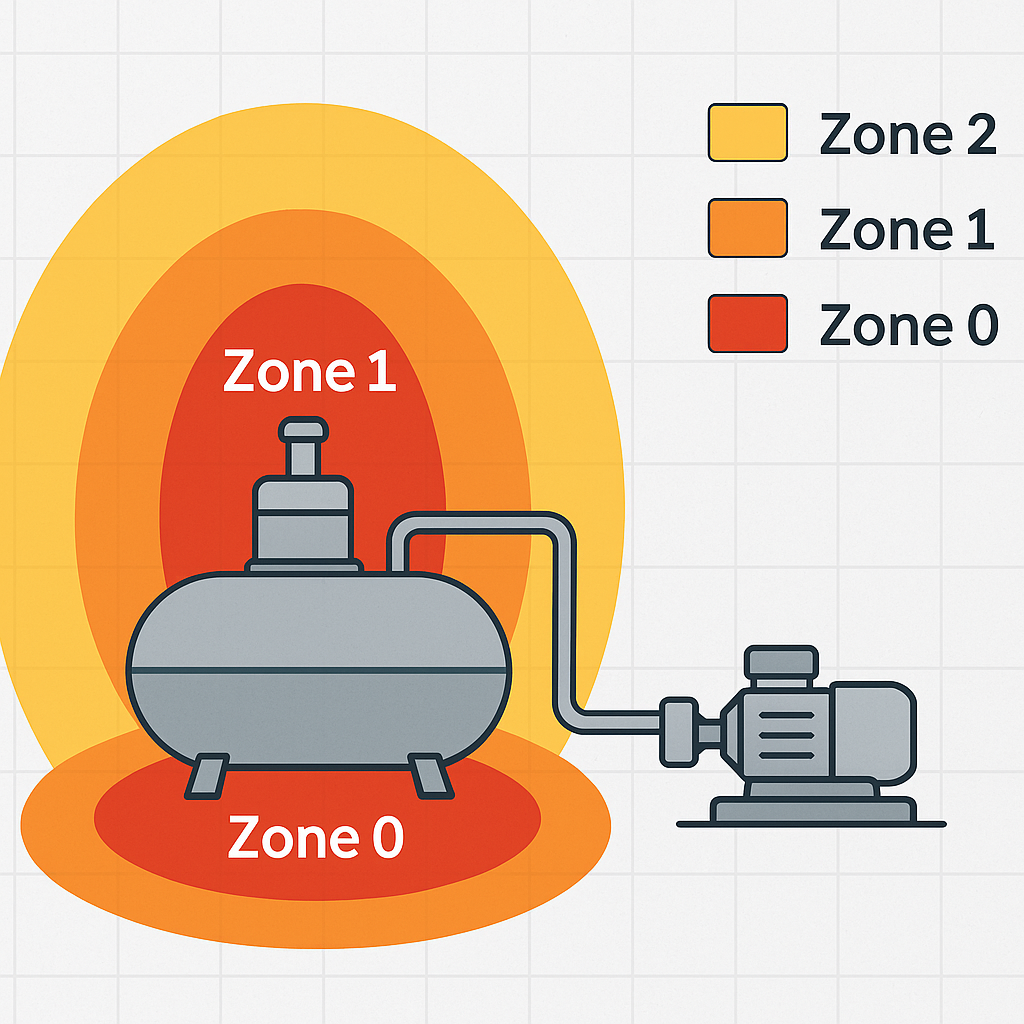

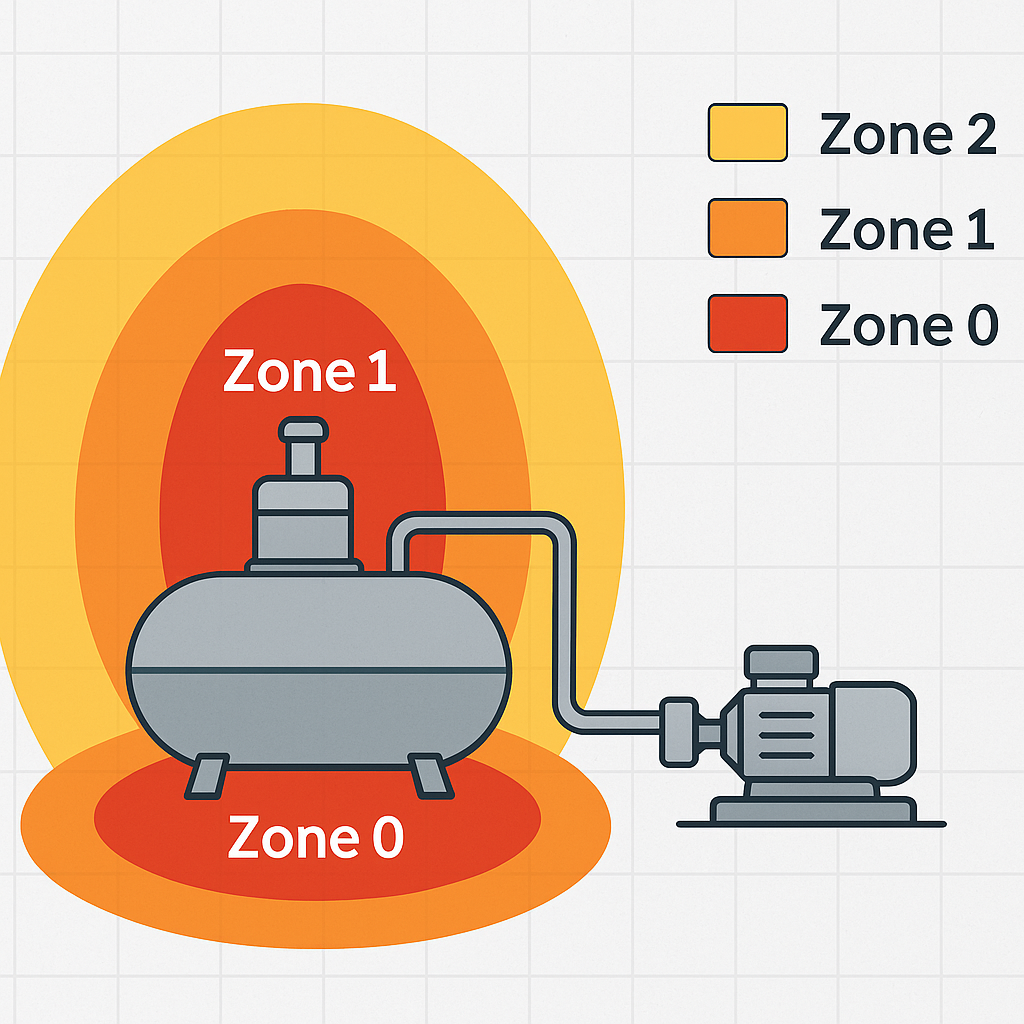

What is Zone Classification?

Zones define the probability of the presence of explosive atmospheres:

| Zone | Gases/Vapors | Dusts |

| Zone 0 | Zone 20 | Continuous hazard (present continuously or long periods) |

| Zone 1 | Zone 21 | Likely hazard under normal operation |

| Zone 2 | Zone 22 | Unlikely but possible hazard under abnormal conditions |

Example:

- Inside a solvent storage tank: Zone 0

- Around tank vents: Zone 1

- Surrounding open areas: Zone 2

What are the Criteria to Declare a Zone?

Key criteria:

- Quantity of Flammable Material – More material = larger zones.

- Frequency of Release – Continuous or occasional?

- Probability of Ignition Sources – Proximity to electrical equipment.

- Ventilation – Well-ventilated areas may reduce zone size.

For example, a poorly ventilated room storing 2,000 liters of ethanol may have extensive Zone 0 and 1 areas.

What Type of Documents Need to Be Reviewed or Prepared?

A robust HAC relies on:

- P&ID (Process & Instrumentation Diagrams)

- Material Safety Data Sheets (MSDS)

- Equipment Layout Drawings

- Ventilation System Designs

- Process Flow Diagrams (PFD)

- Inspection and Maintenance Records

- Previous Incident Reports

The outcome must be a clear HAC Report and HAC Drawings for installers, auditors, and inspectors. TARMS Pakistan prepares all necessary documentation in line with IEC and OSHA compliance audits.

What Types of Risks Are Involved?

Typical risks in hazardous areas include:

- Fire & Explosion Hazards: Ignition of flammable gases, vapors, or dust.

- Equipment Failure: Sparks from motors or switches.

- Electrostatic Discharges: Common in powder handling.

- Human Error: Improper maintenance or hot work.

Example: A spark from non-intrinsically safe equipment in Zone 1 can cause a catastrophic explosion in a paint mixing room.

Conclusion

Hazardous Area Classification is not just a compliance requirement; it is a life-saving process that protects people, assets, and the environment. Organizations should always use qualified professionals and recognized standards to conduct HAC, implement control measures, and keep documentation updated.

Regular training, inspections, and audits ensure that your classification remains valid and effective as your operations evolve.

For tailored HAC studies, professional training, and compliance support in Pakistan, TARMS Pakistan stands ready to guide industries in Islamabad, Lahore, Karachi, and beyond toward safer, compliant operations.

Keywords: Hazardous Area Classification Pakistan, HAC training, Zone classification, Oil & Gas safety audit, TARMS Pakistan risk assessment, HAC consultancy Islamabad, Karachi, Lahore.