Understanding Ledgers, Standards, and Transoms in Scaffolding

Understanding Ledgers, Standards, and Transoms in Scaffolding

By Training and Risk Management Services (TARMS) Pakistan

Published: Updated Edition – 2025

When it comes to scaffolding, knowing the names of its essential components isn’t just about speaking the right lingo—it’s about understanding safety, structural integrity, and legal compliance. Among the most critical structural elements in any scaffold are ledgers, standards, and transoms. These three components are foundational to both the strength and safety of scaffolding used across construction, maintenance, and industrial sites.

At TARMS Pakistan, we train hundreds of professionals in scaffolding safety every year. This article provides a clear explanation of these core parts, complete with examples, risks involved in misuse, and legal safety references to help employers and workers meet national and international compliance standards.

-

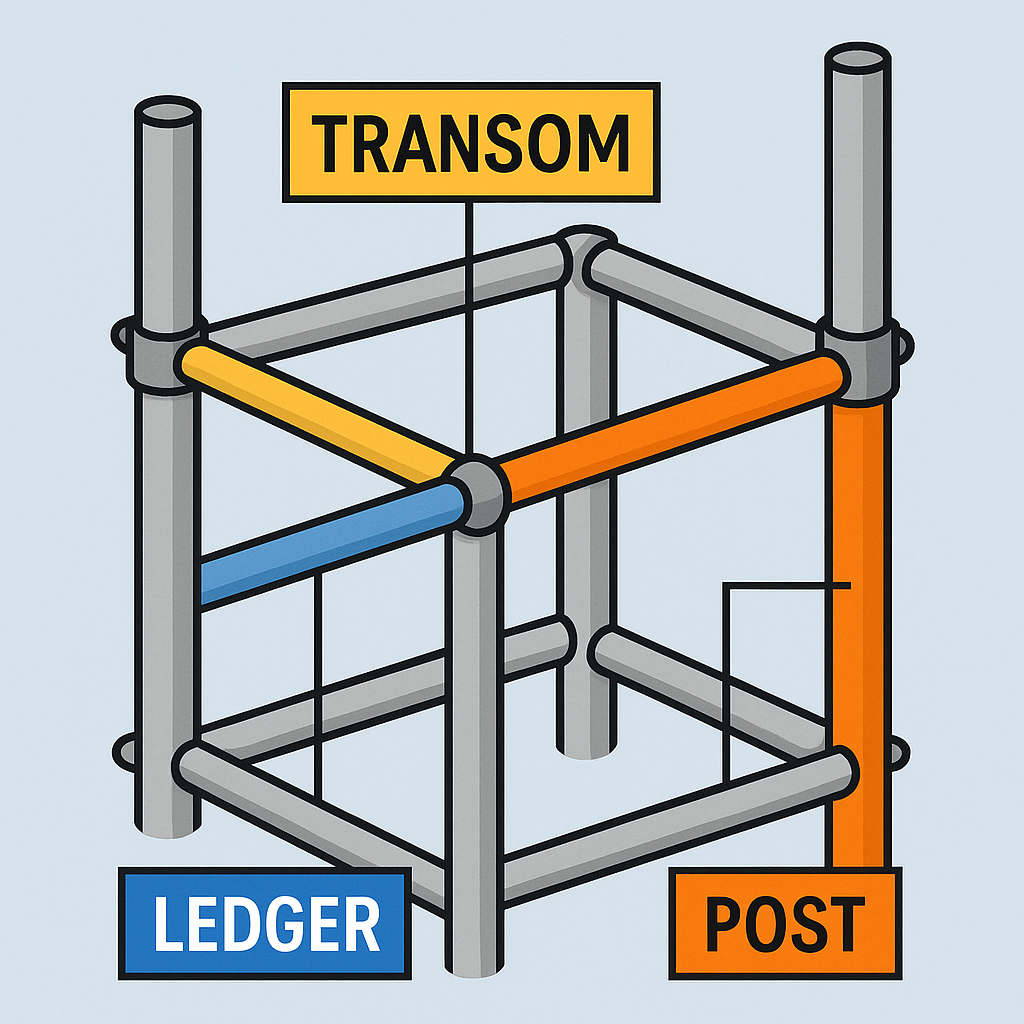

Ledgers – The Horizontal Backbone

A ledger in scaffolding is a horizontal tube that runs parallel to the building façade. It connects the vertical tubes (standards) at various lift levels and acts as the main horizontal support for transoms and working platforms.

Practical Example:

When erecting a 4-level scaffold for plastering work on a commercial façade in Lahore, ledgers are installed at every platform level. These provide support for the scaffold boards and help distribute the load to the standards.

Key Risk:

Missing or poorly connected ledgers can cause platform boards to shift, leading to falls from height—the leading cause of construction site fatalities in Pakistan.

Key Functions:

- Provide horizontal connection between standards

- Support scaffold boards and transoms

- Help maintain scaffold alignment and stability

Legal Reference:

- OSHA 29 CFR 1926.451(b)(4): “Scaffolds shall be planked and decked as fully as possible with safe supports (ledgers and transoms) underneath.”

- Pakistan Building Code 2021, Section 15.5: “All scaffolding platforms must rest on firm ledgers fixed securely at appropriate intervals.”

-

Standards – The Vertical Supports

Standards, also known as uprights, are vertical steel tubes that form the main load-bearing elements of a scaffold. They carry the full weight of the scaffold, including materials and workers, down to the ground via base plates or adjustable jacks.

Practical Example:

At a hospital renovation site in Islamabad, adjustable standards were used on sloping terrain to ensure even platform levels and stability.

Key Risk:

If standards are not vertical or rest on unstable ground, the scaffold can lean or collapse under load, endangering both workers and passersby.

Key Functions:

- Support the vertical load of the structure

- Anchor the scaffold with base plates

- Maintain height and vertical integrity of the scaffold

Legal Reference:

- HSE UK TG20 Guidelines: “Standards must be plumb, continuous, and extend to the base plates or sole boards.”

- Factories Act, Pakistan (1934), Rule 28: “All scaffolding and appliances shall be of sound material, adequate strength, and properly maintained.”

-

Transoms – Cross-Tube Support

Transoms are horizontal tubes fixed at right angles to the ledgers. They provide intermediate support for scaffold boards and increase the rigidity of the scaffold structure by tying the inner and outer standards together.

Practical Example:

During exterior painting of a 5-storey building in Karachi, transoms were installed every 1.2 meters across ledgers to prevent sagging of working platforms.

Key Risk:

Insufficient or incorrectly spaced transoms can cause platform boards to fail, leading to worker injury or material spillage from height.

Key Functions:

- Support scaffold boards perpendicular to ledgers

- Enhance rigidity by locking the horizontal frame

- Resist inward and outward sway

Legal Reference:

- OSHA 1926.451(a)(1): “Each scaffold and scaffold component shall be capable of supporting its own weight and at least four times the maximum intended load.”

- Punjab Occupational Safety and Health Act 2019: “All parts of the scaffold shall be properly braced or tied for adequate strength.”

How These Components Work Together

Ledgers, standards, and transoms form the triangular support system of every safe scaffold. Removing or misplacing even one of these elements can create imbalance, reduce load capacity, or lead to complete scaffold failure.

“The structural safety of a scaffold is only as strong as its weakest component—proper design, spacing, and load calculations are non-negotiable.”

— TARMS Pakistan Instructor’s Manual on Scaffolding Safety

Nutshells: Training = Safety

For builders, safety officers, and contractors alike, understanding these components isn’t just technical knowledge—it’s life-saving knowledge. At TARMS Pakistan, our certified training programs empower workers to identify, assemble, and inspect these elements correctly, reducing risks of collapse, falls, and legal violations.

Whether you’re working on a high-rise in Dubai or setting up facade access in Pakistan, scaffolding safety begins with the basics done right.

Legal and Training References:

- OSHA 29 CFR 1926 Subpart L – Scaffolding

- HSE UK – General Access Scaffolds TG20 Guidelines

- Pakistan Building Code 2021 – Chapter 15: Temporary Structures

- Punjab OSH Act 2019

- TARMS Pakistan: Scaffold Erection & Inspection Course Manual

Looking to train your team in scaffold safety and inspection?

📞 Contact TARMS Pakistan today to schedule a certified program that ensures safety and legal compliance at every site.